Specifications

-

Head Pressures:

Medium and High Head Pressure Applications -

-

Size Range:

6" - 120" -

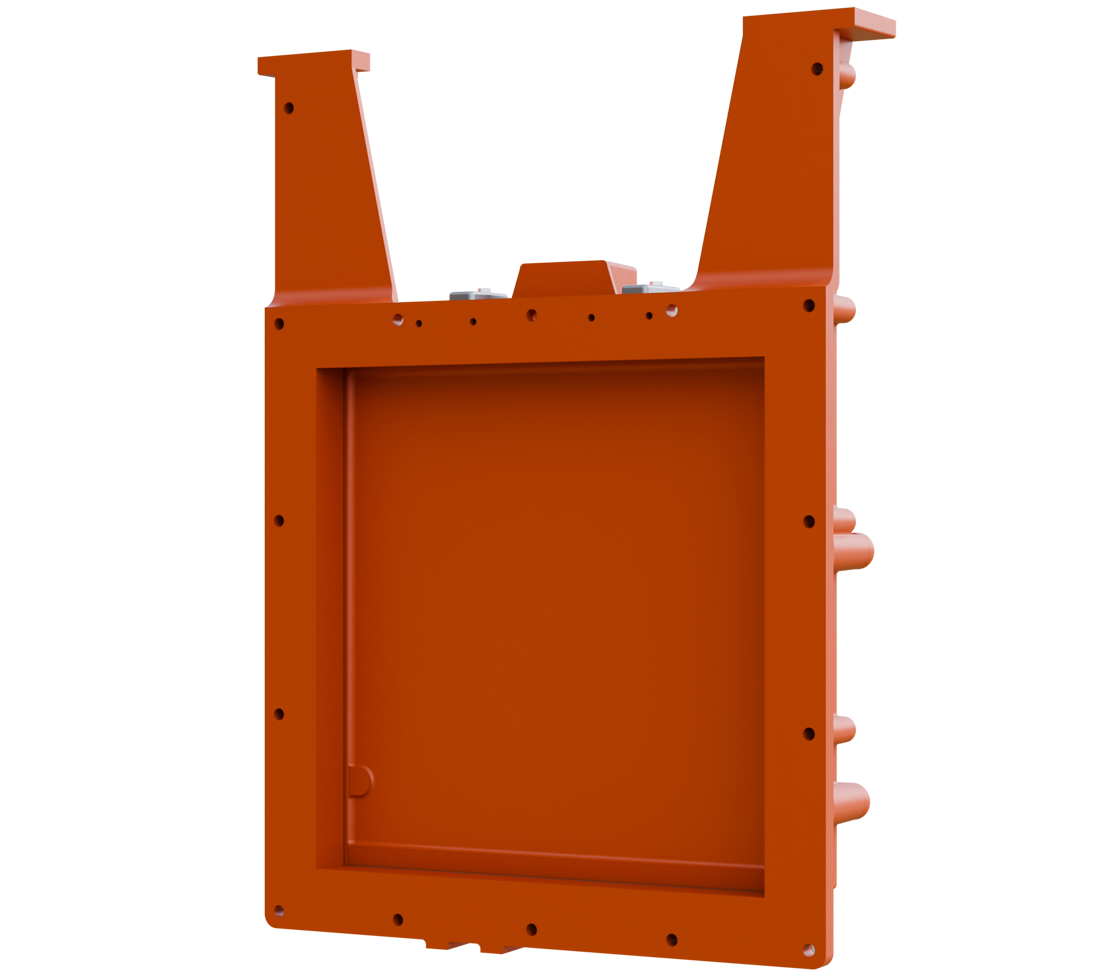

Frame & Slide Material:

Ductile Cast Iron ASTM A-536 -

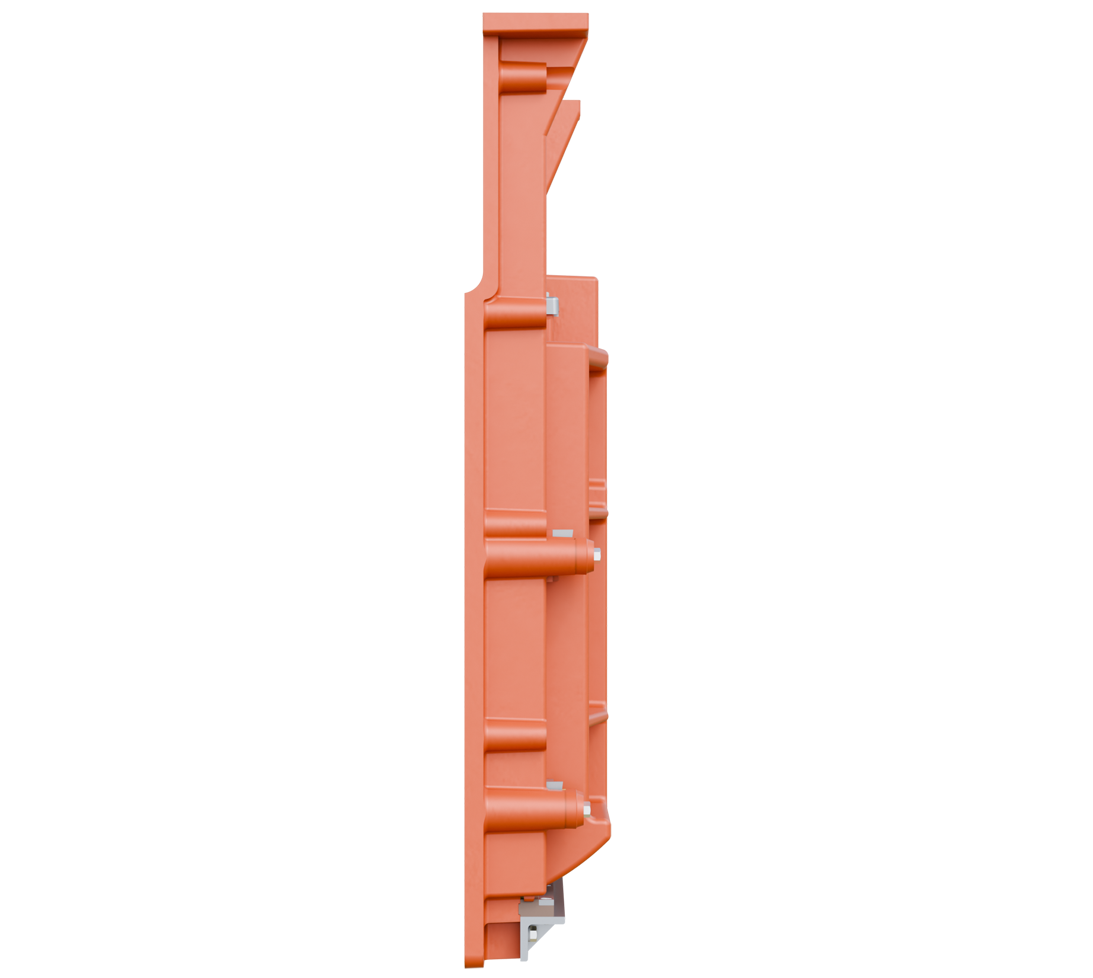

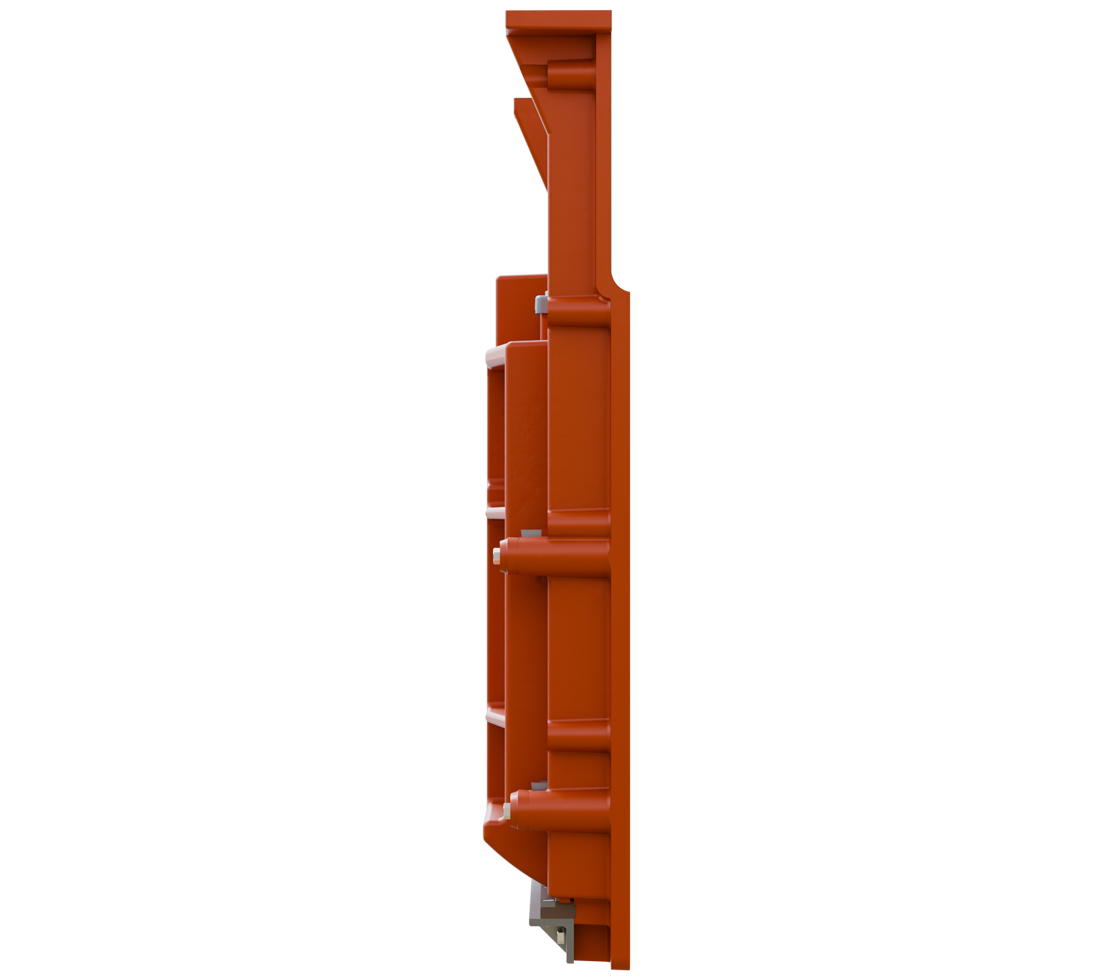

Frame Type:

Flatback or Extended Flange Back -

Stem Material:

Stainless Steel ASTM A-276 Type 304 or 316 -

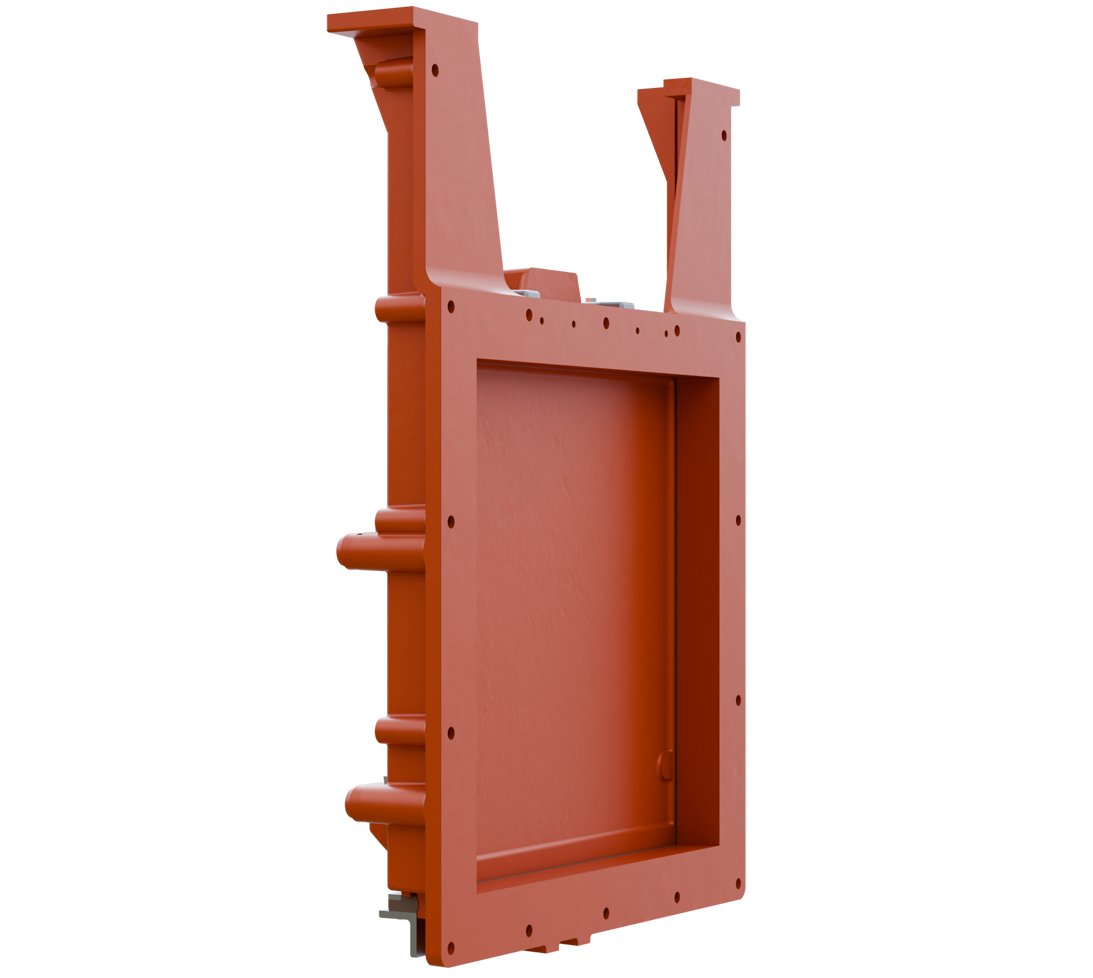

Mounting Type:

Direct Wall Mount or Wall Thimble (Type E, F, or MJ) Mount or Pipe Mount -

Yoke Material:

Steel ASTM A-36 or Stainless Steel ASTM A-240, A-276 Type 304 or 316 -

Mounting Orientation:

Vertical or at an incline for oil seal assembly applications -

Seat & Wedge Material:

Naval Bronze ASTM B-21 Alloy 48200 -

Actuation:

Non-Geared Handwheel, Bevel Gear, Electric, Electro-Hydraulic -

Sealing Material:

Neoprene ASTM D-2000 -

Design/Test Standard:

AWWA C-560 -

Assembly and Mounting Hardware:

Stainless Steel ASTM F-593 & F-594 Type 304 or 316

Features & Benefits

• Thick, highly rigid frame and cover to handle high heads and environments with floating debris. Cover and frame design fully tested to meet or exceed design specifications with finite element analysis. Stress and deflection are measured based on both seating and unseating heads and other external loading. Analysis allows gate to perform with maximum reliability and minimum leakage.

• Proven design as one of the industry’s oldest manufacturers of cast iron sluice gates, Waterman has thousands in operation worldwide.

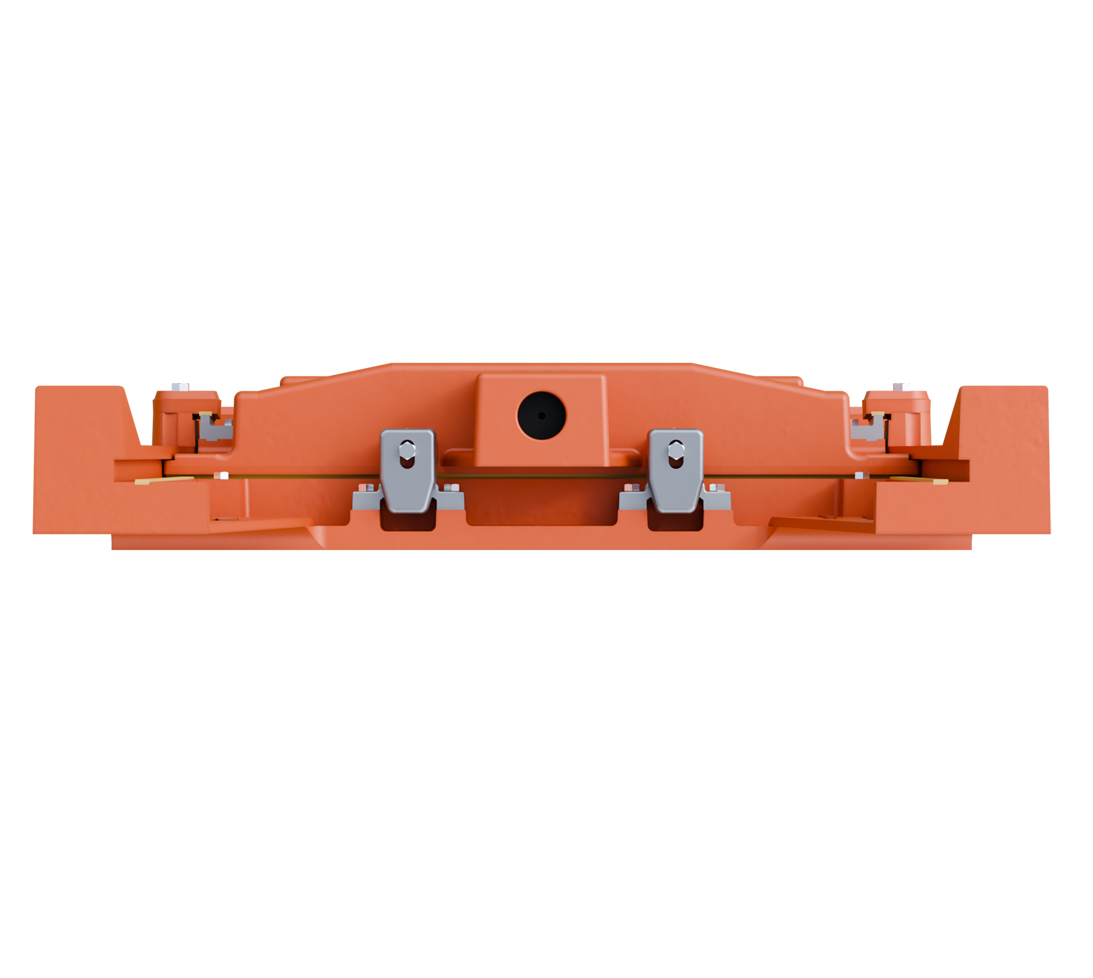

• Low leakage machined metallic seating surfaces create a reliable tight seal, minimizing leakage. Seating faces are corrosion-resistant and are mechanically locked into the gate frame and cover in full-width dovetail grooves. Seats are made of a malleable material that is formed into the grooves. The fullwidth dovetail design prevents the possibility of leakage between the seat material and the castings.

• High performance adjustable wedge system offers easier maintenance and proven performance. Assures proper reliable closure of top, bottom and sides. (Bottom wedges not required with Q-Seal Flushbottom Seal)

• Choice of ductile iron (other material options may be available upon request).

• Design flexibility with the industry’s largest selection of sizes and mounting options: gate shapes available in square and rectangular, with square, rectangular or round openings to meet the needs of even the most unusual applications.

• Offered for a full range of mounting options: gates offered for submerged service, wall mounting, flange mount and more.