Specifications

-

Size Range:

3”-72” -

Temperature Range:

0º-250ºF -

Operating Pressure:

150B – 150 PSI; 250B – 250 PSI -

Body Materials:

ASTM A536 65-45-12 Ductile Iron -

Body Seat Material:

ASTM A276 T316SS -

Disc Materials:

ASTM A536 65-45-12 Ductile Iron -

Seat Materials:

EPDM -

Shaft Materials:

150B - ASTM A276 T304, 250B - ASTM A564 T630 (17-4) -

Body Style:

FLG (3”-72”) MJ (4”-48”) FLGxMJ (6”, 8", 12", 16”) -

Design/Test Standard:

AWWA C504 -

Flange Drilling:

FLG – ANSI B16.1 Class 125 & 250 MJ – ANSI/AWWA C111/A21.11 -

Certifications:

NSF 61, NSF 372 -

Face to Face:

AWWA C504 -

Exterior Fasteners:

18-8 Stainless Steel -

Actuation:

Traveling Nut, Worm Gear, Electric, Hydraulic, Pneumatic, Lever

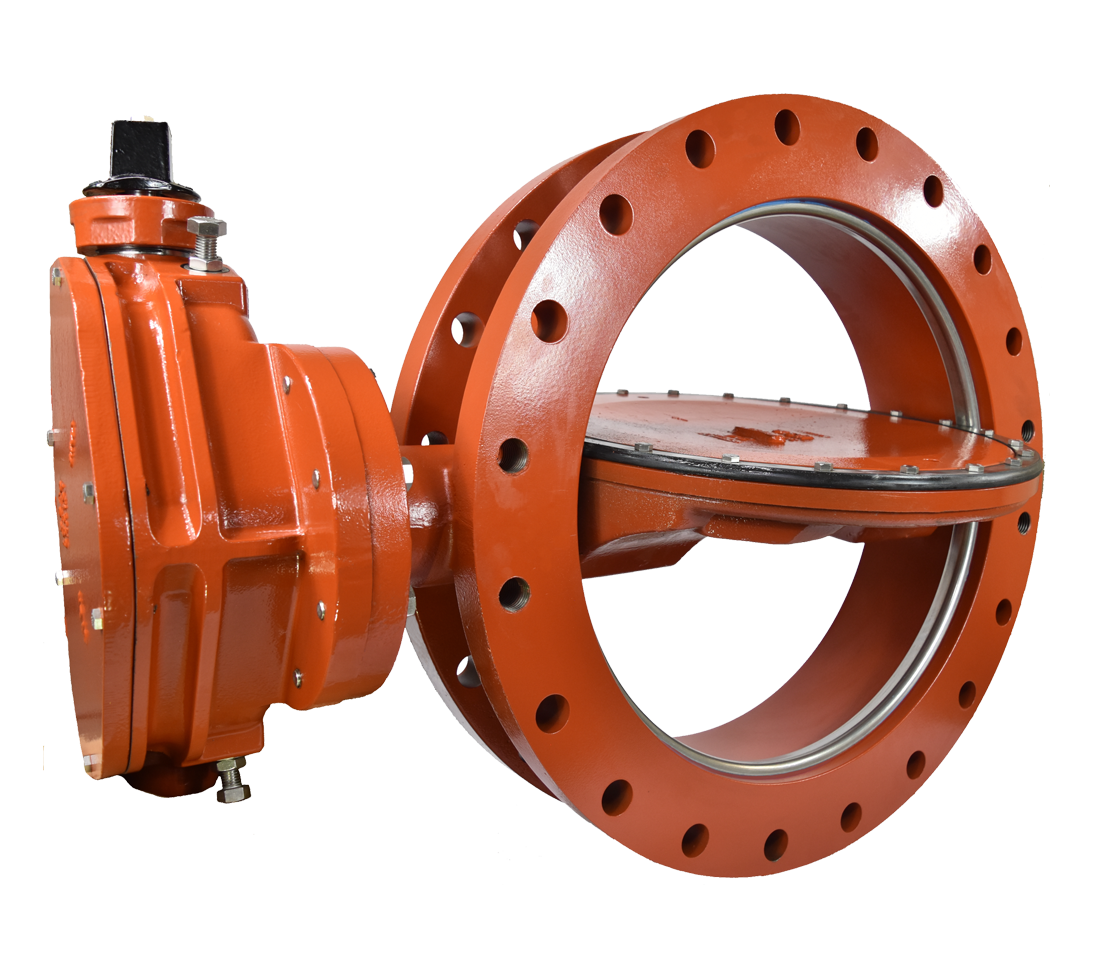

Features & Benefits

- Butterfly Valves come standard with an integrally cast actuator mounting pad, machined and drilled in accordance with ISO-5211 and MSS SP-101. This allows for direct mounting of manual and automated actuators without the need of additional pieces or adapters, providing a more compact and rigid arrangement.

- Stainless steel meets or exceeds AWWA C504: Class 150B – 304 stainless steel Class 250B – 630 stainless steel. Single-piece (3”-12”). Two-piece (14”-72”).

- Butterfly Valve Bodies consist of heavy duty ASTM A536 ductile iron that are designed to meet or exceed AWWA C504.

- EPDM rubber is vulcanized to a 304 stainless steel ring and attached to the vane utilizing self-locking, stainless steel cap screws. The body ring seat is composed of 316 stainless steel, forming an uninterrupted 360-degree seal. Butterfly Valve vane rubber seat ring is easily field replaceable.

- Heavy duty A536 ductile iron meets or exceeds AWWA C504.

- Self-adjusting V-type packing that increases the sealing force with the increase in line pressure. Accessible without dismantling the valve, per AWWA C504.

- Full metal-to-metal contact, vane to shaft connection utilizing a stainless steel torque plug.

- Nylon bearings are sized to meet or exceed the AWWA C504 specification for axial pressure loads. The bearings are self-lubricating and require no maintenance.